EPE Foam Roll Manufacturer in Chonburi

Three D Interpack Co., Ltd. is a leading manufacturer of EPE (Expanded Polyethylene) foam and comprehensive protective packaging solutions. We produce and supply high-quality EPE foam in various formats—rolls, sheets, bags, and custom-formed products—using advanced machinery and specialized technologies, including rust-preventive and anti-static solutions.

Through a standardized industrial production process, we carefully select premium raw materials and maintain strict quality control at every stage. This ensures consistent product quality, durability, and reliable performance across a wide range of industrial applications.

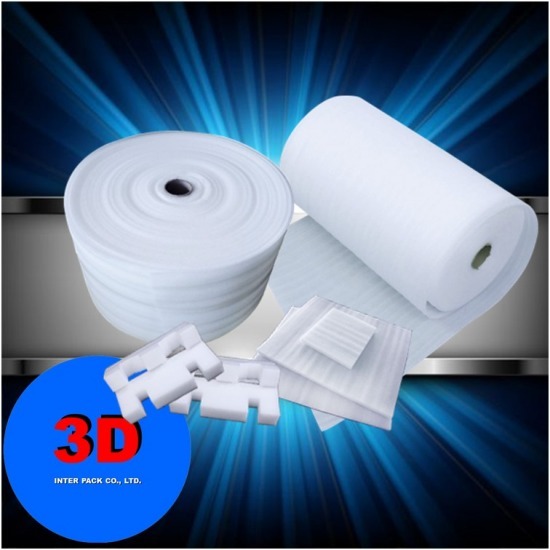

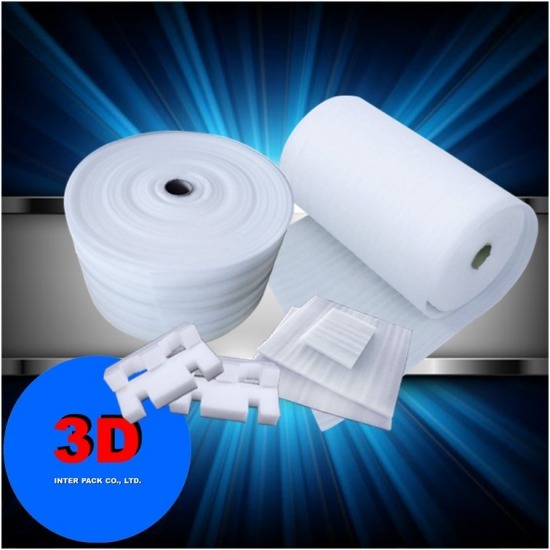

EPE Foam Rolls and Sheets

Suitable for: General product wrapping, furniture protection, and construction applications.

- EPE Foam Rolls: White foam with a soft, smooth surface, lightweight construction, and high flexibility. These rolls provide excellent protection against scratches and impacts during transportation. Various thicknesses are available to meet specific requirements. Thickness: 0.5 mm to 10 mm (0.5, 1.0, 1.5, 2.0, 3.0, 4.0, 5.0, 6.0, 8.0, 10 mm) Standard widths: 100 cm and 130 cm Roll lengths: Available in various options (50 m, 100 m, 150 m, 300 m)

- EPE Foam Sheets: Pre-cut to required dimensions, offering convenience for immediate packaging applications. Sheets can be layered to enhance protection.

Key properties include dust resistance, minor moisture resistance, and a soft surface that prevents product damage.

Additional Services

- Custom color production: In addition to standard white foam, we offer production in blue, pink, green, orange, and black (made-to-order with a 7-day lead time).

- Film lamination: Optional lamination to increase durability and improve appearance.

Custom Die-Cut Foam and Partition Products

Suitable for: Automotive parts, electrical appliances, and components with specific shapes.

- Custom design and cutting of foam to match the exact shape of customer products, including rectangular, circular, or complex configurations.

- Foam partitions and blocks are produced from thicker foam (20 mm and above) using precision die-cutting or heat blade cutting.

These products securely hold items in place, preventing movement during transportation and providing superior protection compared to standard wrapping methods.

Specialty Technical Foam Products

Suitable for: Metal parts manufacturing and electronics production.

- Anti-Rust Foam (VCI Foam): Foam impregnated with rust-preventive chemicals that release colorless, odorless molecules to form a protective coating on metal surfaces, inhibiting corrosion. This eliminates the need for rust-preventive oils and reduces associated costs.

- Anti-Static Foam: Pink foam specifically designed for packaging electronic components, providing effective protection against electrostatic discharge damage.

EPE Foam Bags

Suitable for: Automotive parts, office equipment, and computer peripherals.

Custom-sized foam bags are produced by heat-sealing EPE foam, offering convenient, ready-to-use packaging that enhances the professional appearance of shipped products.

Die-Cut and Formed Foam Cushions

We provide custom die-cut foam inserts that are precisely shaped to fit individual products. These inserts can be cut, formed, and laminated to the required thickness, ensuring a secure fit that prevents movement, impacts, and damage during handling and transportation. This solution is ideal for applications requiring foam that conforms exactly to the product shape.

Key Advantages of EPE Protective Foam

- Can be formed into blocks or precisely die-cut to any required shape.

- Available as foam bags or pouches, providing comprehensive protection against impacts, dust, and moderate moisture.

- Foam sheets can be used to wrap products prior to boxing, safeguarding against abrasion and impact damage during transportation.

- Anti-static black or pink foam sheets are available for sensitive electronic products.

- Lightweight construction minimizes additional shipping costs based on weight.